Technical features

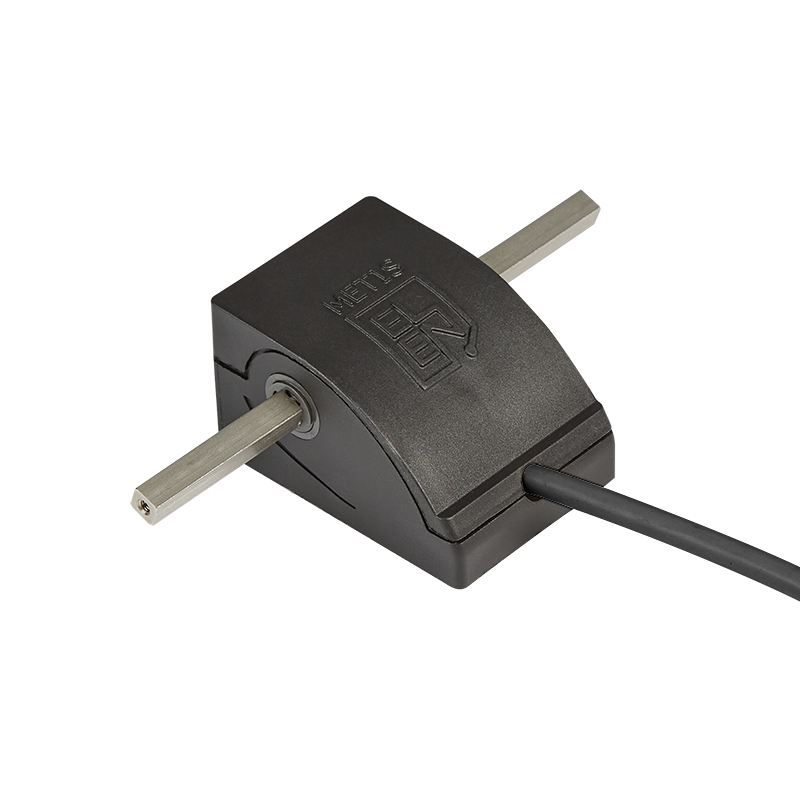

The Elen Metis series throttle accelerators are controls designed for all electrically powered work vehicles with a steering wheel, in particular for vehicles used for moving and lifting loads and for professional cleaning.

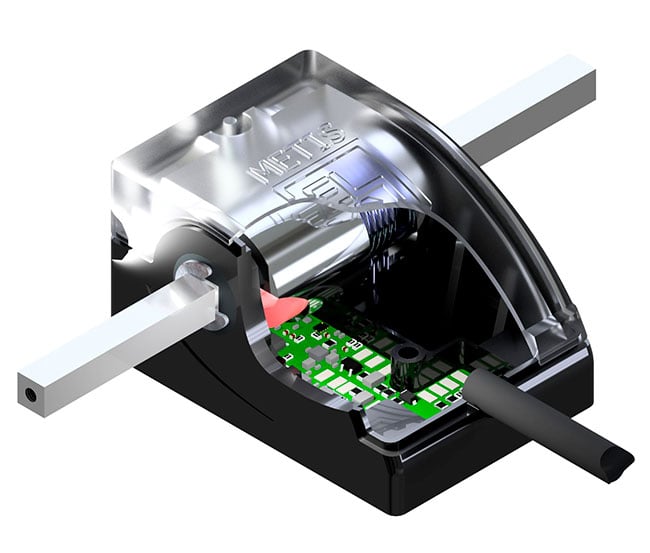

The Hall-effect operating principle, the firmware for managing the signal and trigger thresholds and the innovative magnetic return system make the mechanics extremely simple and reliable (reducing the presence of contact parts to the essential) and the signal precise, repeatable and programmable. These features, combined with the resin coating and sealed housing, make the product suitable for use in harsh environments.

The principle of operation is that a Hall sensor intercepts the field of the magnet integrated with the lever pin and provides an output signal that is linear and proportional to the angle of rotation.

Mechanical configurations

The Metis throttle accelerator is available in 2 versions, which differ in the size of the cover and the number of fixing holes (standard version and lowered version).

Applications

The Metis throttle is designed for use on pallet trucks, forklifts, tractors, cranes, electric tractors and professional cleaning machines.

Construction features